Discover how Luton’s community adapts to road closures and infrastructure upgrades, turning short-term disruption into long-term sustainability and resilience. Learn more now!

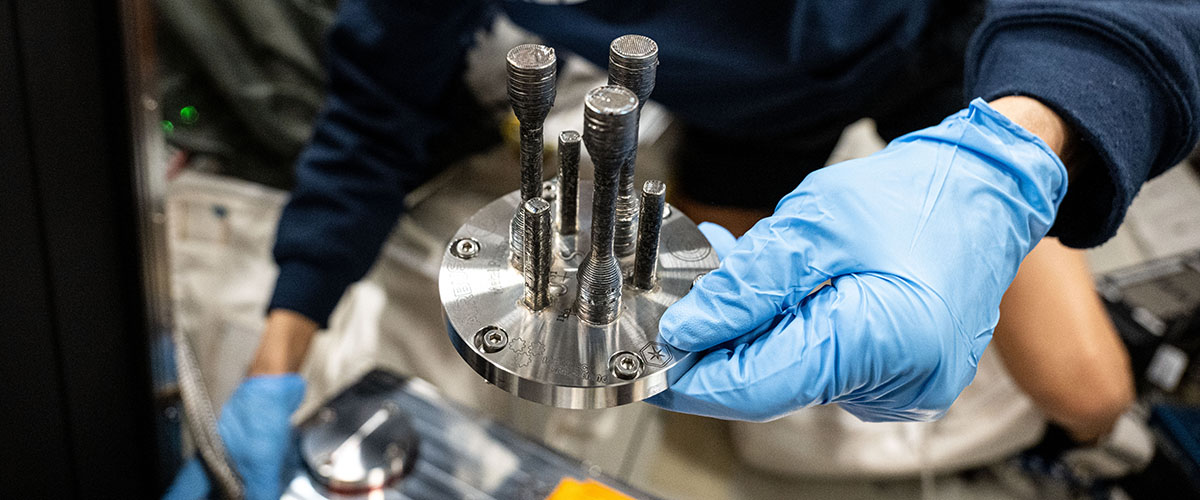

In a groundbreaking achievement for space exploration, Cranfield University has played a pivotal role in producing the first-ever metal part 3D printed in space. This milestone represents a significant step forward in the realm of off-world manufacturing and holds immense potential for future space travel.

Collaboration in the Cosmos

The success of this project highlights the collaborative nature of space research, with Cranfield University experts working alongside international partners to push the boundaries of what's possible beyond Earth's atmosphere. The ability to create metal components in space could revolutionise how we approach spacecraft maintenance, repair, and even construction of new structures in orbit or on distant planets.

A Milestone in Space Manufacturing

Cranfield University has achieved a significant breakthrough in space exploration by contributing to the production of the first metal part ever 3D printed in space. This accomplishment marks a crucial step forward in the development of off-world manufacturing capabilities, opening up new possibilities for future space missions and long-term habitation beyond Earth.

The groundbreaking project involved close collaboration between Cranfield University experts and international partners, showcasing the power of global cooperation in advancing space technology. By successfully creating a metal component in the unique environment of space, the team has demonstrated the potential for on-demand manufacturing of critical parts and tools during space missions.

Implications for Future Space Travel

The ability to 3D print metal parts in space could revolutionise how we approach spacecraft maintenance and repair. Instead of relying solely on pre-packaged spare parts or waiting for resupply missions from Earth, astronauts could potentially fabricate necessary components on-site. This capability could significantly enhance the self-sufficiency of space missions, reducing dependency on Earth-based supply chains and increasing the feasibility of long-duration space exploration.

Furthermore, this achievement paves the way for the potential construction of larger structures in orbit or on other celestial bodies. The technology could be instrumental in establishing permanent bases on the Moon or Mars, where the ability to manufacture structural elements and equipment using local resources would be invaluable.

Cranfield University's Expertise

While the specific details of Cranfield University's role in the project are not provided in the source material, the institution's involvement underscores its position as a leader in aerospace engineering and advanced manufacturing technologies. The university's contribution to this historic achievement highlights the importance of academic research and expertise in driving innovation in the space sector.

The Future of Space Manufacturing

As space agencies and private companies set their sights on ambitious goals like establishing a permanent human presence on the Moon and sending crewed missions to Mars, the ability to manufacture components in space will become increasingly crucial. This successful demonstration of 3D printing metal parts in space represents a significant milestone on the path to realising these aspirations.

The technology has the potential to reduce the cost and complexity of space missions by minimising the need to launch all necessary equipment from Earth. It also offers the flexibility to adapt to unforeseen challenges during missions, allowing astronauts to create custom solutions to problems as they arise.

While this achievement marks a major step forward, it is likely only the beginning of a new era in space manufacturing. Further research and development will be necessary to refine the technology, expand the range of materials that can be used, and scale up the size and complexity of parts that can be produced in space.

Advancing Space Exploration Through Innovation

Cranfield University's contribution to the first 3D-printed metal part in space represents a significant leap forward in space exploration technology. This achievement not only demonstrates the feasibility of off-world manufacturing but also highlights the potential for transforming how we approach space missions.

The ability to produce metal components in space could lead to more efficient and adaptable spacecraft designs. Future missions might carry raw materials and 3D printing equipment instead of a vast array of spare parts, allowing for greater flexibility and resource optimisation. This shift in approach could significantly reduce launch costs and payload requirements, making space exploration more economically viable.

Fostering Interplanetary Sustainability

As humanity looks towards establishing a long-term presence on other celestial bodies, the importance of in-situ resource utilisation becomes paramount. The technology pioneered by Cranfield University and its partners could be a crucial stepping stone towards creating self-sustaining outposts on the Moon or Mars.

By harnessing local resources and manufacturing capabilities, future space colonies could reduce their reliance on Earth-based supply chains. This level of autonomy is essential for the viability of long-term space habitation and could pave the way for more ambitious exploration missions to the outer reaches of our solar system.

Inspiring the Next Generation of Space Innovators

Cranfield University's involvement in this groundbreaking project serves as an inspiration for students and researchers in the fields of aerospace engineering and advanced manufacturing. It demonstrates the real-world impact of academic research and the potential for universities to play a pivotal role in shaping the future of space exploration.

This achievement may spark increased interest in space-related studies and careers, potentially leading to a new wave of innovations in the field. As more young minds are drawn to the challenges and possibilities of space manufacturing, we can expect to see accelerated progress in this area in the coming years.

Collaborative Frontiers in Space Research

The success of this project underscores the importance of international collaboration in advancing space technology. By pooling resources, knowledge, and expertise from various institutions and agencies worldwide, the space community can tackle complex challenges more effectively.

This collaborative approach sets a precedent for future space endeavors, encouraging open sharing of information and joint efforts to overcome the hurdles of space exploration. As we continue to push the boundaries of what's possible beyond Earth's atmosphere, such partnerships will be crucial in driving innovation and achieving ambitious goals in space exploration.